news center

How to effectively maintain the crusher bearings?

2024-08-30

How to effectively maintain the crusher bearings?

In the wave of industrialization, crushers have become indispensable heavy equipment in industries

such as mining and construction with their powerful crushing capacity and wide application scenarios.

However, with the increase in frequency of use and the harsh working environment, the bearings of crushers,

as their key components, are often under great pressure and are prone to wear or damage.

Therefore, how to effectively maintain the bearings of crushers and extend their service life has

become a problem that every mechanical equipment operator and maintenance technician must face.

To keep the bearings of crushers in the best condition, you first need to understand their working principles and use environment.

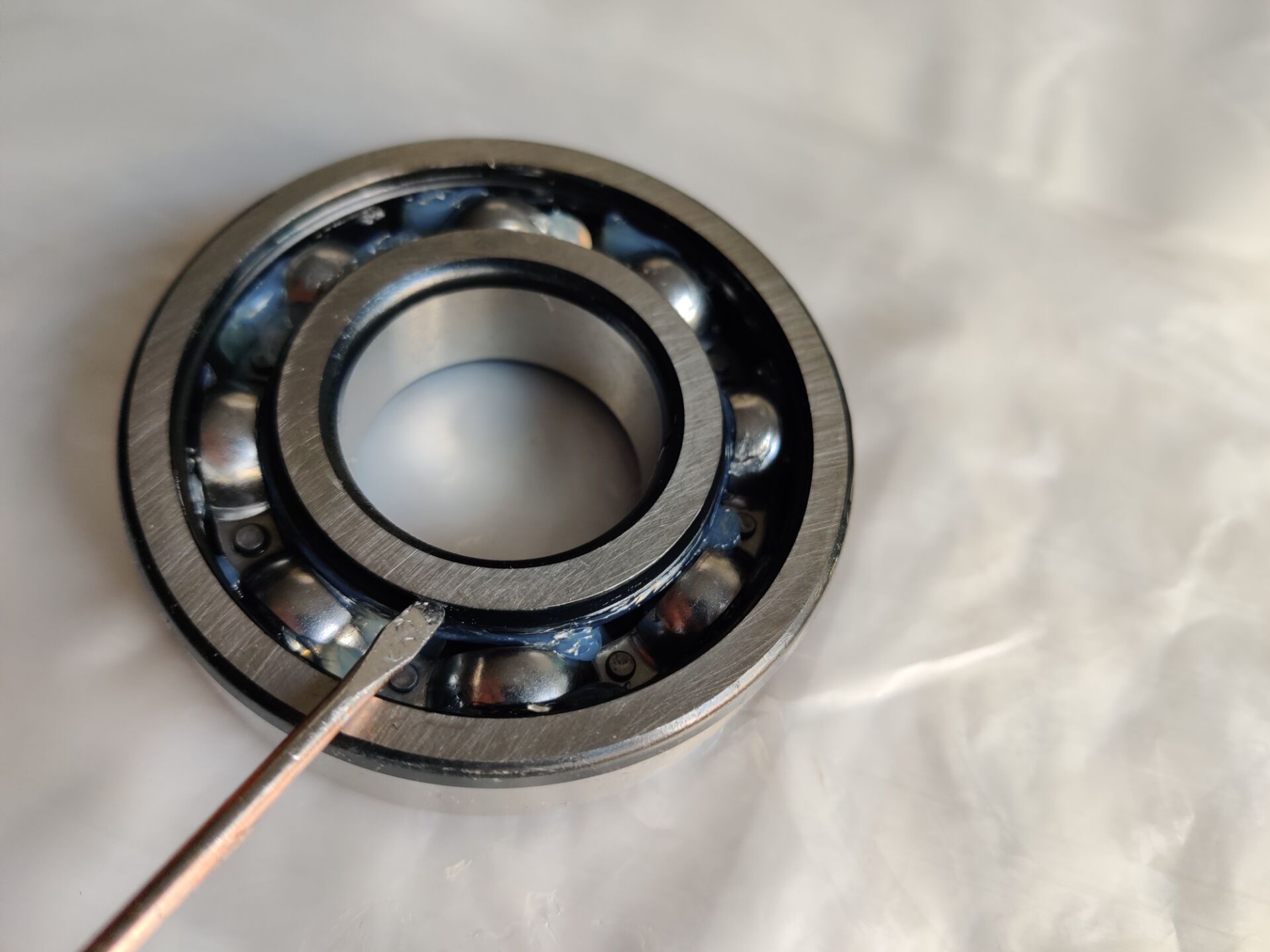

Bearings are mechanical elements that use rolling friction between rolling elements (such as balls, rollers, etc.) and inner and outer rings to support rotating parts.

In crushers, bearings must not only withstand the impact and vibration generated by material crushing,

but also resist the influence of harsh factors such as dust and moisture.

This requires us to focus on the lubrication, cleaning and sealing of bearings during maintenance.

Lubrication is the basis of bearing maintenance.

Good lubrication can reduce the friction coefficient between rolling elements and inner and outer rings,

reduce the temperature and wear of bearings, and thus extend their service life.

Generally speaking, grease with appropriate viscosity and performance should be selected according to factors such as the operating temperature,

speed and load of the bearing. At the same time, it is also necessary to pay attention to regularly check the state of the grease.

If it is found to be discolored, dry or reduced, it should be replaced or supplemented in time.

Cleaning is the key to preventing premature damage to the bearing.

Sealing is an effective means to protect the bearing from external contamination.

The bearings in the crusher usually use oil seals or rubber seals to achieve the sealing effect.

During the maintenance process, it is necessary to regularly check whether the seals are intact.

If they are damaged, new seals should be replaced in time.

In addition,it is also necessary to avoid excessive impact and vibration of the bearings to avoid deformation or falling of the seals.

In addition to the above basic maintenance measures, there are some tips to help us better maintain the bearings of the crusher.

For example, when replacing a new bearing, a thin layer of lubricating grease can be applied to the inner ring of

the bearing to help reduce the friction resistance during the initial startup; when storing unused bearings,

they should be placed in a dry and cool environment to avoid direct sunlight and rain soaking; when carrying bearings,

they should be handled with care to avoid bumps and falls.

Through correct maintenance methods, we can effectively extend the service life of the bearings in the crusher,

ensure the stable operation of the equipment, and reduce the downtime losses caused by failures.

If you need deep groove ball bearings, please do not hesitate to contact us!