news center

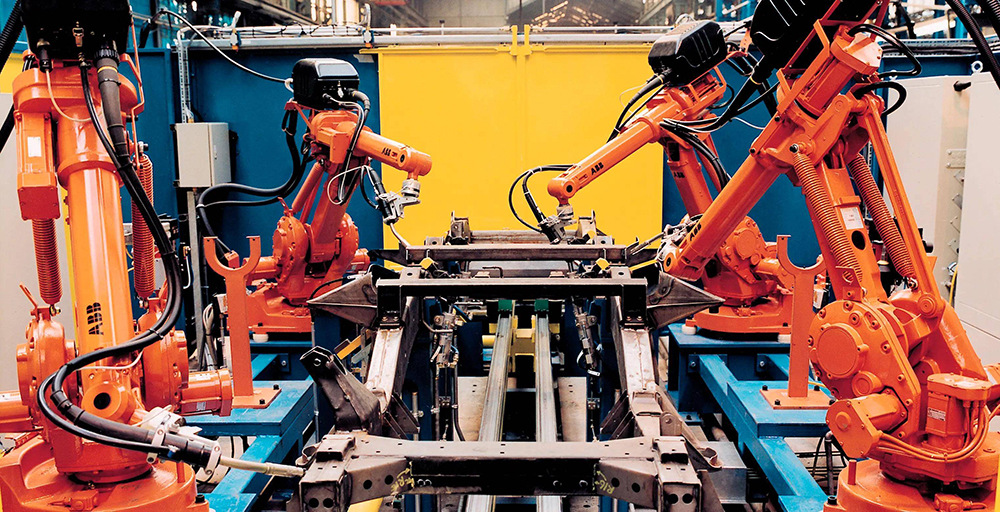

What are the key types of bearings used in industrial robots

2024-08-27

What are the key types of bearings used in industrial robots?

Bearings commonly used include crossed roller bearings, thin-section bearings, and angular contact ball bearings, which are essential for handling the precision and load requirements of robotic joints and arms.

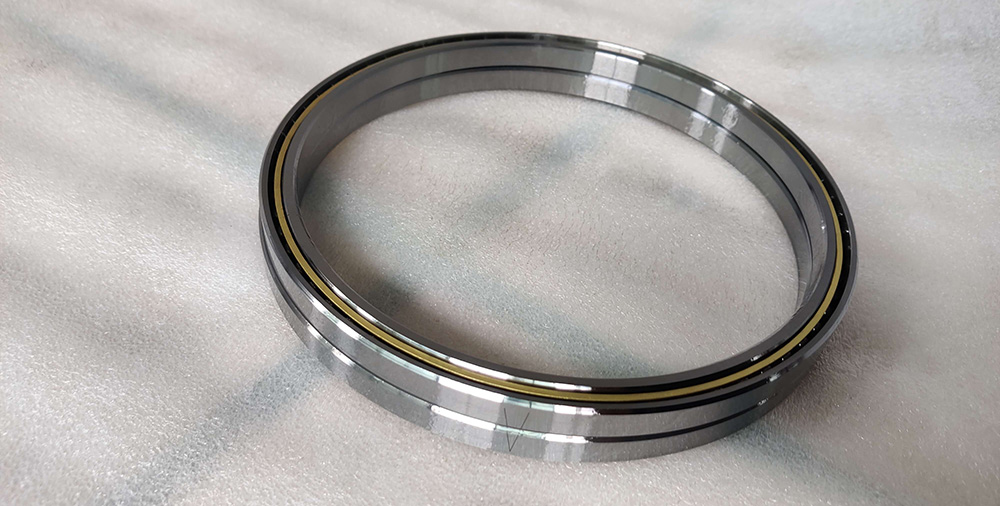

Crossed Roller Bearings: These bearings are designed with rollers arranged at right angles to one another in a V-groove, allowing them to support loads in multiple directions simultaneously. This makes them particularly well-suited for applications requiring high precision and rigidity, such as in the joints and arms of industrial robots where both radial and axial loads need to be managed effectively.

Thin-Section Bearings: Thin-section bearings are engineered to be compact and lightweight while still providing high performance. Their reduced size and weight make them ideal for robotic applications where space is limited, yet the need for maintaining accuracy and load-bearing capacity remains critical. These bearings help ensure smooth and precise movements in robotic joints, enhancing the overall efficiency of the system.

Angular Contact Ball Bearings: Known for their ability to handle high axial loads and provide excellent accuracy, angular contact ball bearings are essential in scenarios where robots need to maintain precise control and positioning. These bearings are often used in robotic arms where maintaining a high level of precision under varying load conditions is crucial for the robot’s functionality.

Welcome to contact us if you have any request about bearings used in industrial robots.