news center

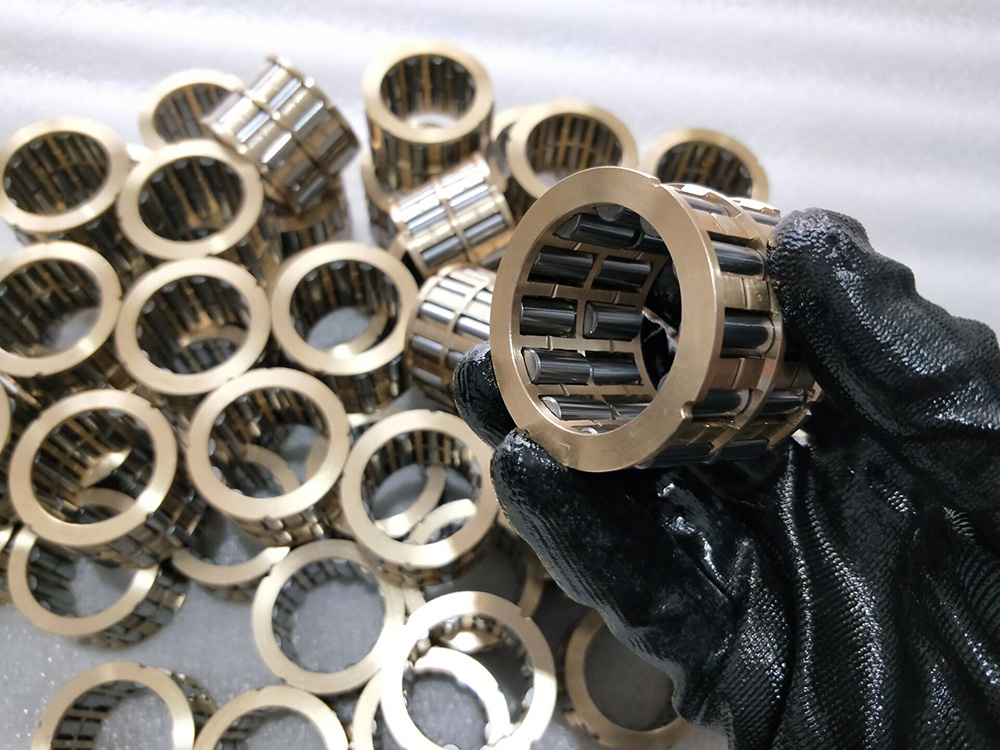

What is a needle roller bearing?

2024-10-08

A needle roller bearing is a type of rolling-element bearing that uses long, thin cylindrical rollers (resembling needles) to reduce friction between moving parts. They are designed to handle radial and axial loads while occupying minimal space.

Below FAQs provide a comprehensive overview of needle roller bearings, addressing common concerns and inquiries that users typically have.

1. What are the advantages of needle roller bearings?

·High Load Capacity: They can support heavier loads compared to ball bearings of the same size due to their larger contact area.

·Compact Design: Their small cross-section allows for lightweight and space-efficient designs.

·Lower Cost: Generally more economical than other types of bearings, especially in drawn-cup designs.

·Low Maintenance: Many needle roller bearings require minimal maintenance, provided they are adequately lubricated.

2. What applications commonly use needle roller bearings?

Needle roller bearings are widely used in various applications, including:

·Automotive: Transmissions, torque converters, and rocker arm pivots.

·Industrial Machinery: Gearboxes, pumps, and hydraulic systems.

·Domestic Appliances: Power tools, washing machines, and compressors.

3. How do needle roller bearings differ from other types of bearings?

Needle roller bearings have a higher length-to-diameter ratio than other roller bearings, allowing them to handle higher loads in a smaller space. Unlike ball bearings, they provide better load distribution due to their larger surface area.

4. What types of needle roller bearings are available?

Common types include:

·Caged Needle Roller Bearings: Contain a cage to separate the rollers.

·Drawn-Cup Needle Roller Bearings: Have a thin-walled outer ring for lightweight applications.

·Thrust Needle Roller Bearings: Designed for axial loads with rollers positioned perpendicular to the shaft.

5. Can needle roller bearings handle misalignment?

Needle roller bearings are generally sensitive to misalignment. Proper installation is crucial to ensure optimal performance and longevity.

6. What is the typical operating temperature range for needle roller bearings?

Needle roller bearings can typically operate effectively at temperatures ranging from -40°C to +120°C (-40°F to +248°F), depending on the materials used and lubrication conditions.

7. How do you maintain needle roller bearings?

Regular maintenance includes ensuring proper lubrication and inspecting for signs of wear or contamination. Keeping the operating environment clean can also prolong their lifespan.

8. What factors should be considered when selecting a needle roller bearing?

Considerations include load capacity, speed requirements, operating environment (temperature and contamination), and available space for installation.

9. Are there any limitations to using needle roller bearings?

While they offer many advantages, needle roller bearings may not perform well under high radial loads compared to other bearing types like spherical or tapered roller bearings. They also require precise alignment during installation.

If you have any inquiry about needle roller bearings, please feel free to contact us!