About DSYC

About DSYC Bearing

Shandong DSYC Bearing Co.,LTD. is located in China famous bearing manufacturing base-Linqing city, Shandong province. We are a bearing manufacturer integrating Research & Development, design, production and sales. The company was gradually developed from a small workshop to a standardized enterprise in 2015.

The company specializes in the production of ball bearings, such as deep groove ball bearings, angular contact ball bearings and thin-section ball bearings.

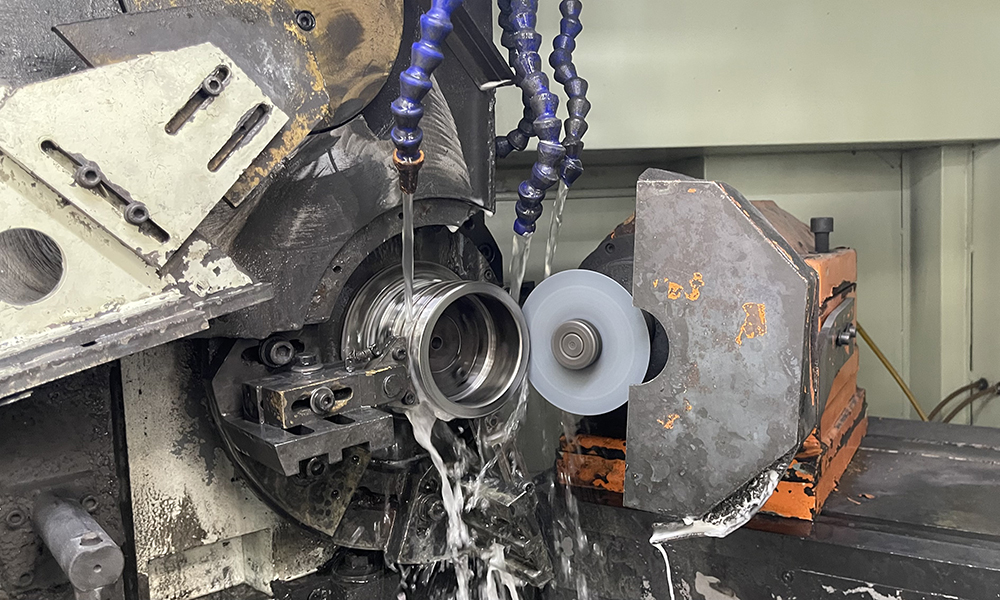

The company is equipped with advanced testing instruments and production equipment. The testing instruments include coordinate measuring machine, hardness tester, roundness measuring instrument,vibration detector, bearing clearance measuring instrument, bearing runout measuring instrument,etc. Production equipment include CNC Lathes, polishing and super-finishing machines, ultrasonic cleaning equipment, assembly machines, lubrication and greasing machines, packaging machines, etc.

Factory

The factory covers an area of more than 18,000 square meters and a building area of more than 8,500 square meters. It has more than 200 processing and testing equipment for producing precision bearings and a group of high-quality production and development technicians, with strong customized development capabilities.

The company has established a complete quality assurance system with customers as the focus, and passed the ISO9001:2015 international quality system certification in 2023. The company has advanced process equipment and testing equipment, and has established and improved strict quality assessment and various rules and regulations.

The annual output of various types of bearings is more than 2 million sets, with an output value of more than 50 million yuan. The products are sold well in more than 60 countries, and a dozen provinces and cities across the China, and are used for various types of precision machine tools, CNC machine tools, precision machinery, automobiles, engineering machinery, transportation machinery, and agricultural machinery enterprises. DSYC has become a shining pearl in the bearing industry.

Testing Laboratory

In a bearing factory, testing equipment is a key component to ensure product quality and performance. Our main testing equipment includes vibration analyzers, which monitor the vibration status of bearings to identify potential faults; ultrasonic detectors, which provide early warnings to detect problems such as insufficient lubrication; roundness and roughness meters, which measure the geometry and roughness of the bearing surface to ensure that it meets the design requirements; hardness testers, which measure the hardness of materials to verify their wear resistance and service life; metallographic microscopes, which analyze the microstructure of materials; and 3D coordinate measuring machines, which accurately measure the size and shape of bearings.

Testing methods include condition monitoring, which monitors the changes in the state of bearings during use through real-time data collection and analysis, fatigue life testing to evaluate the durability of bearings, and noise testing to identify potential problems. With these high-tech equipment, the factory is able to effectively monitor and evaluate the quality of bearings, thereby ensuring the reliability and safety of the final product.

Warehouse

Effective warehouse management is crucial to bearing production. It directly affects production efficiency and product quality, and can reduce inventory costs, reduce losses and improve production efficiency. The management measures we take include real-time updating of inventory information to ensure efficient outbound and inbound storage, as well as keeping the warehouse dry and ventilated to avoid direct sunlight and external pollution.

The indoor temperature of the warehouse is generally maintained between 10℃ and 20℃, and the relative humidity does not exceed 60%. In addition, the warehouse for storing bearings needs to meet specific conditions: the temperature should be maintained between 10℃ and 20℃, the maximum should not exceed 30℃, and the minimum should not be lower than 5℃; the relative humidity should be controlled below 60% to prevent the bearings from rusting or deforming. At the same time, our warehouse is also equipped with good dust and moisture-proof facilities to ensure the quality of bearing products.

Packaging

The export packaging of our bearings can ensure that the products are not damaged during transportation and meet international standards. According to relevant standards, the outer packaging of bearings should follow JB/T 3016-2004 "Rolling bearings packaging box technical conditions" and JB/T 4036-2004 "Rolling bearings transport pallets and large wooden boxes". These standards specify packaging materials, containers, methods and printing requirements to ensure the sturdiness and durability of the packaging, and to meet the needs of multiple transshipments and lifting and loading and unloading.

In actual operation, our bearings are usually placed in special customized cartons or wooden boxes. Cartons have moisture-proof and dust-proof properties, while wooden boxes must meet international transportation standards to prevent pests and rot. In addition, there are plastic bags and other materials in the packaging for protection to reduce the impact of vibration and impact on the bearings. In terms of labeling, the product information, specifications, quantity and precautions should be clearly marked on the packaging to facilitate customs inspection and customer identification.

Through these meticulous packaging measures, the risk of loss during transportation can be effectively reduced and the bearings can be ensured to arrive safely at the destination.