News Center

Deep groove ball bearing noise level knowledge: How to choose a quieter bearing?

2025-04-15

What is the bearing noise level?

As one of the most commonly used bearing types in mechanical equipment, the noise level of deep groove ball bearings during operation directly affects the overall noise performance of the equipment. Bearing noise level refers to the standard classification of the intensity and quality of sound produced when the bearing is operating under specific conditions.

When the bearing rotates at high speed, the friction, vibration and lubrication status between the rolling element and the raceway will generate sound waves of different frequencies and intensities. These sound waves are what we often call "bearing noise". High-quality bearings can keep this noise to a minimum while ensuring performance.

Main sources of bearing noise

1. Manufacturing precision factors: including groove roundness, surface roughness, steel ball precision, etc.

2. Assembly factors: such as clearance control, cage fit, etc.

3. Lubrication factors: improper grease selection or insufficient lubrication

4. Usage factors: improper installation, excessive load or high speed

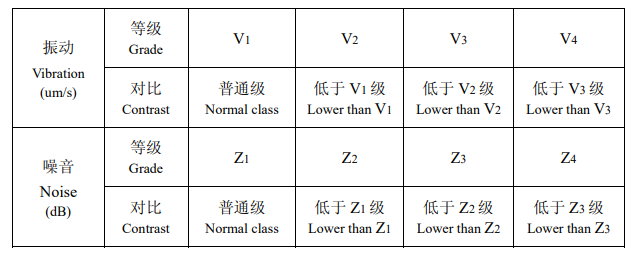

Common noise level standards

1. Z1/Z2/Z3 grades (Chinese standards)

This is the most commonly used bearing noise level standard in China:

- Z1 grade: ordinary grade, no special quiet requirements

- Z2 grade: low noise level, 5-10dB quieter than Z1

- Z3 grade: extremely low noise level, 5-10dB quieter than Z2

2. Noise level in ABEC standards

Although ABEC focuses mainly on dimensional accuracy, bearings with high precision grades (such as ABEC-7/9) are usually quieter:

- ABEC-1: ordinary grade

- ABEC-3: medium precision

- ABEC-5/7/9: high precision, relatively lower noise

3. SKF's "quiet" series

The international brand SKF has a special "quiet" bearing series, such as:

- E2: high efficiency and low friction

- Explorer: high performance and low noise

- Quiet: professional quiet series

How to choose the appropriate noise level?

The following factors should be considered when selecting the noise level of a bearing:

1. Application scenarios:

- Household appliances (electric fans, washing machines): at least Z2

- Office equipment (printers, scanners): Z3 is recommended

- High-precision instruments: Special silent bearings are required

2. Cost factors:

- The price of Z3-grade bearings may be 20-50% higher than that of Z1-grade

- The price of special silent bearings may double

3. Maintenance cycle:

- Low-noise bearings usually have a longer life and longer maintenance intervals

Practical suggestions for reducing bearing noise

1. Correct installation: Use professional tools and avoid direct knocking

2. Proper lubrication: Choose the right type and amount of grease

3. Regular maintenance: Replace aging bearings in time

4. Match the load: Do not overload the bearing

5. Consider the environment: Special bearings are required for high temperature or polluted environments

Future development trends

As people's requirements for quietness in living and working environments increase, bearing silent technology is also developing:

- Application of new materials (ceramic hybrid bearings)

- More sophisticated manufacturing processes (nano-level processing)

- Smart bearings (built-in vibration and noise monitoring)

- Environmentally friendly low-noise lubrication technology

Choosing bearings with appropriate noise levels can not only improve the equipment usage experience, but also extend the equipment life.

When purchasing bearings, you may wish to consult us and choose the best cost-effective product based on actual needs.