News Center

How do I select the right bearing for an electric motor?

2015-12-15

How do I select the right bearing for an electric motor?

Consider load type (radial or axial), speed, operating temperature, and environment (e.g., moisture, dust).

Below are some of the most frequently asked questions about bearings for electric motors:

1.What types of bearings are commonly used in electric motors?

Deep groove ball bearings

Angular contact ball bearings

Cylindrical roller bearings

Insulated bearings (e.g., ceramic-coated or hybrid bearings)

2.Why are insulated bearings used in electric motors?

To prevent electrical discharge that can cause bearing damage, especially in motors using variable frequency drives (VFDs).

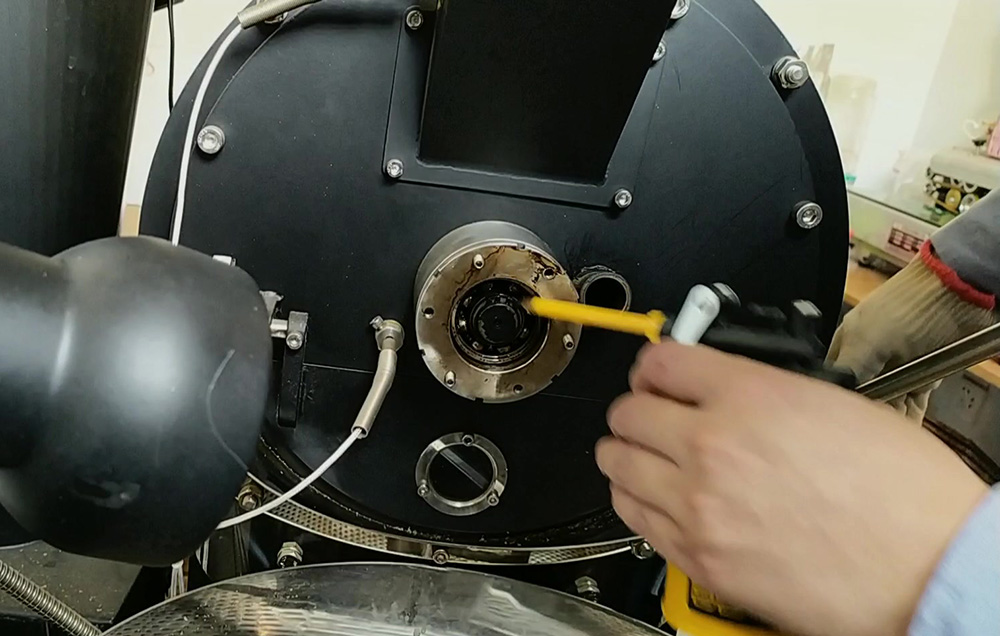

3.What is the purpose of grease in electric motor bearings?

To reduce friction, minimize wear, and provide a barrier against contaminants.

4.How often should electric motor bearings be lubricated?

It depends on the operating conditions and type of grease. For most motors, lubrication intervals range from every 6 months to a year.

5.What is the typical lifespan of bearings in an electric motor?

Bearings can last 5 to 10 years or more under normal operating conditions if properly maintained.

6.What is the maximum speed rating for electric motor bearings?

The speed rating depends on the bearing type and size. High-speed applications may require hybrid bearings with ceramic balls.

7.How does vibration affect electric motor bearings?

Excessive vibration can lead to premature bearing failure. Vibration analysis is often used to monitor bearing health.

8.What is the role of hybrid bearings in electric motors?

Hybrid bearings, with ceramic balls and steel races, reduce electrical conductivity and handle higher speeds and temperatures.

9.What are the common materials used for electric motor bearings?

Bearing steel (52100 chrome steel)

Ceramic materials (for hybrid or fully ceramic bearings)