News Center

How much do you know about electric motor bearings?

2021-10-26

How much do you know about electric motor bearings?

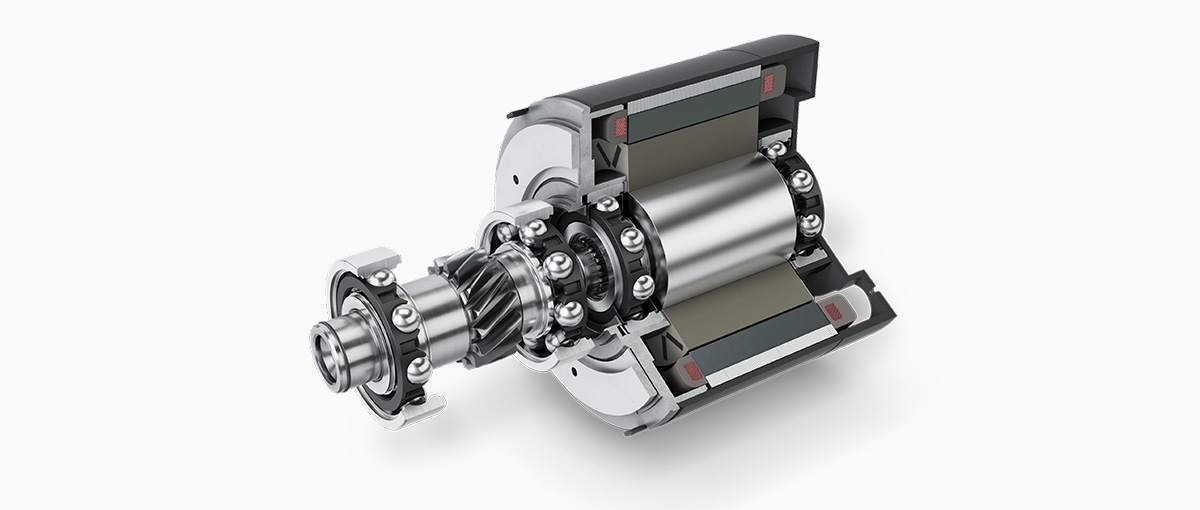

Electric motor bearings are critical components that support the rotating elements of electric motors, ensuring smooth operation and longevity. Here are some key insights regarding electric motor bearings:

Types of Bearings Used in Electric Motors

Deep Groove Ball Bearings: These are the most common type of bearings used in electric motors. They can handle both radial and axial loads, making them versatile for various applications, including small appliances and fans. Their design allows for high-speed operation due to the extensive contact area between the balls and raceways.

Angular Contact Ball Bearings: Designed to accommodate both radial and axial loads, these bearings are ideal for applications where precise positioning is required. They are commonly used in high-speed motors, machine tools, and robotics.

Needle Roller Bearings: Characterized by their small diameter and high load capacity, needle roller bearings are often used in compact electric motor designs where space is limited, such as automotive starter motors.

Spherical Roller Bearings: These bearings can handle heavy radial and axial loads and are often used in large industrial electric motors where misalignment may occur.

Self-Aligning Ball Bearings: These bearings accommodate misalignment between the shaft and housing, reducing friction and wear caused by misalignment, making them suitable for various electric motor applications.

Considerations for Bearing Selection

When selecting bearings for electric motors, several factors must be considered:

Load Conditions: The type of loads (radial vs. axial) that the motor will experience.

Speed Requirements: The operational speed of the motor influences bearing choice; high-speed applications require specific bearing designs.

Environmental Factors: Exposure to contaminants or extreme temperatures may necessitate sealed or shielded bearings.

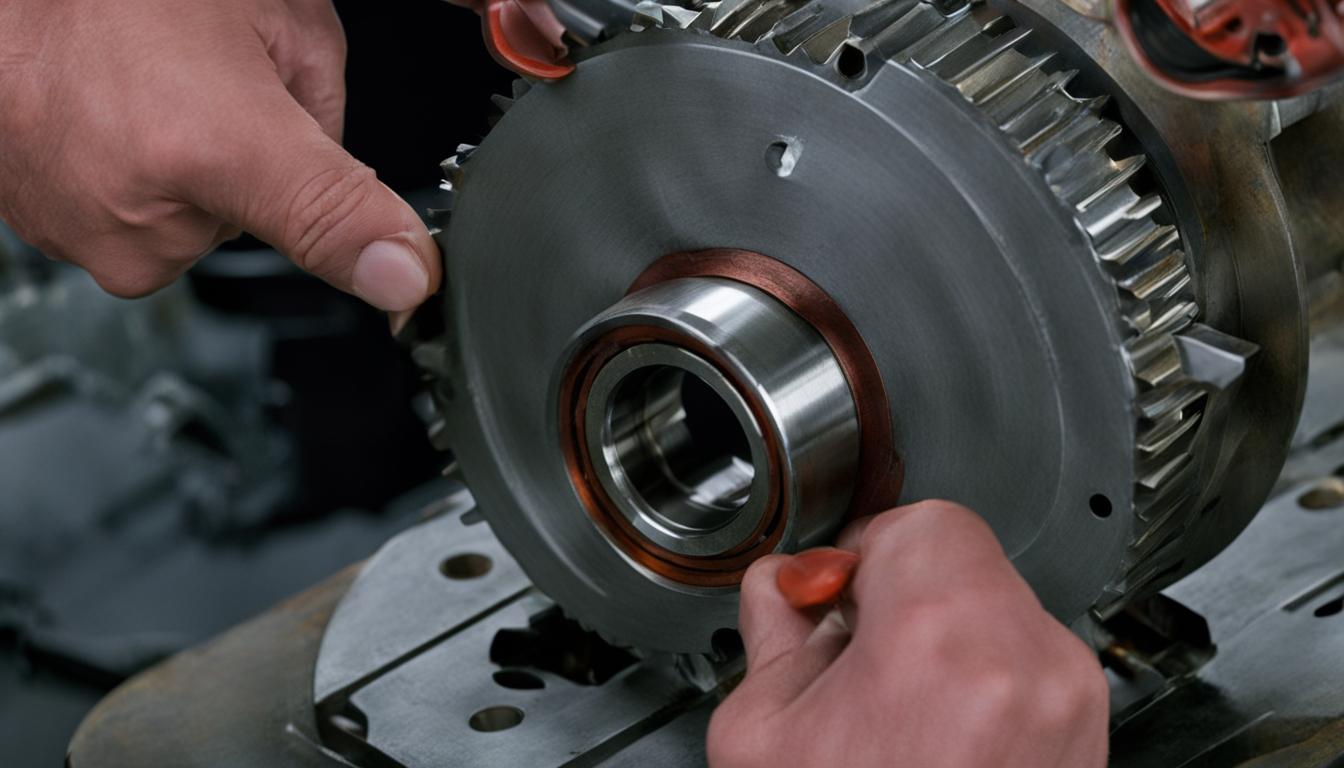

Lubrication Needs: Proper lubrication is essential for reducing friction and preventing premature failure.

Conclusion

In summary, electric motor bearings play a vital role in ensuring efficient operation across various applications. The selection of appropriate bearing types—such as deep groove ball bearings, angular contact ball bearings, or needle roller bearings—depends on specific operational requirements including load conditions, speed, and environmental factors.

With ongoing innovations in bearing technology, especially for high-speed applications like electric vehicles, manufacturers continue to enhance performance and reliability in electric motors.

Welcome to contact us if you have any request about DSYC bearings!