News Center

How to correctly select, use, disassemble and lubricate bearings?

2018-01-25

How to correctly select, use, disassemble and lubricate bearings?

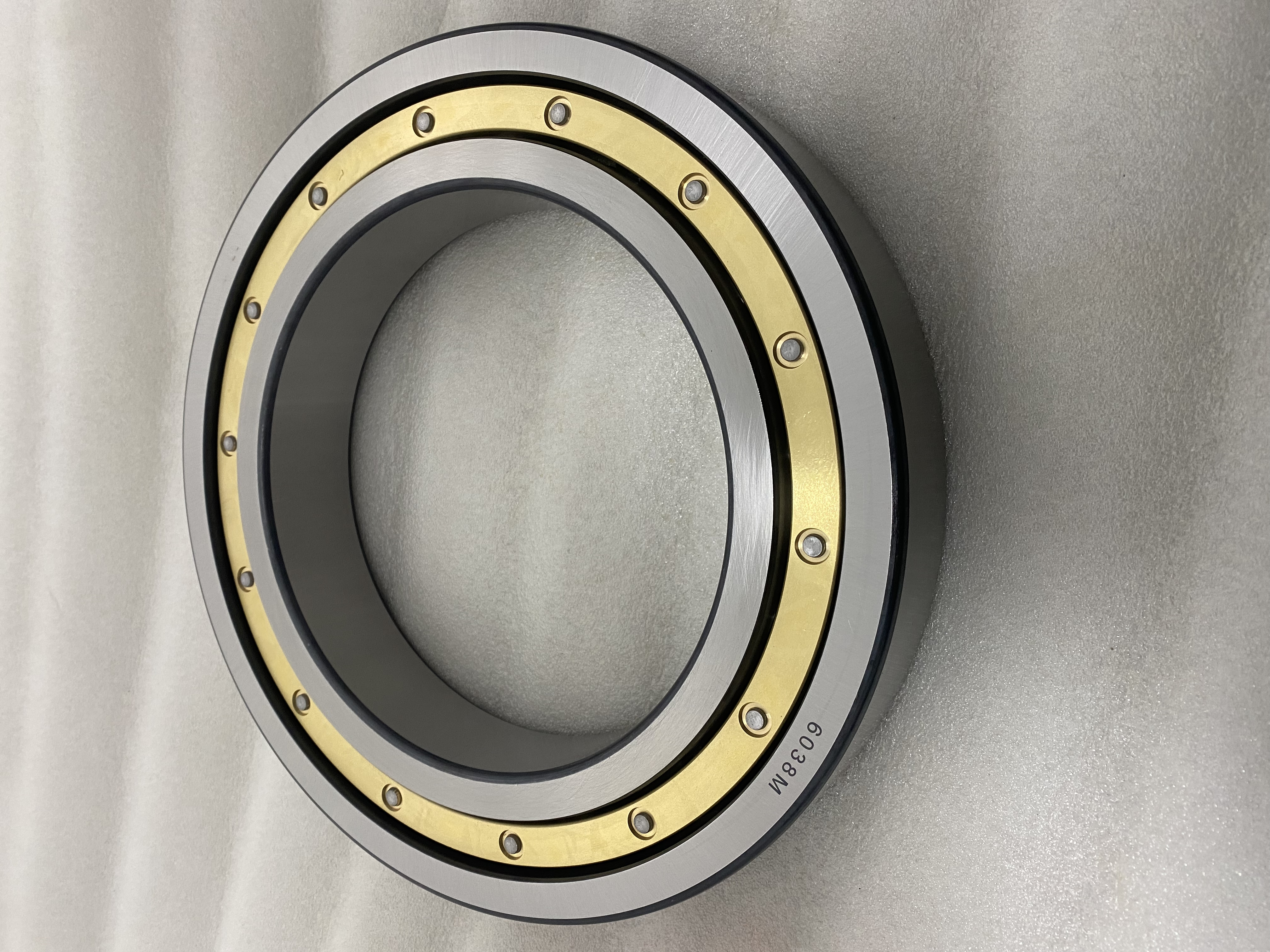

As an important part of precision machinery, the selection, use, disassembly and lubrication of bearings are crucial. The correct selection can ensure the best performance and life of the equipment, while reasonable use and maintenance can avoid failures and extend the service life of the bearings.

When selecting bearings, the type, size and configuration of the bearings should be determined according to the working conditions of the equipment.

For example, for high-speed rotation applications, lubricating oil-lubricated bearings with low friction coefficients should be selected; for applications with high ambient temperatures, models that can withstand high temperatures should be selected.

In the process of using bearings, correct installation and lubrication are the key to ensuring their normal operation.

The bearings should be thoroughly cleaned before installation, and special tools should be used to press them evenly to avoid direct knocking on the bearings to cause damage. In terms of lubrication, appropriate lubricants should be selected according to the use environment and working conditions of the bearings. Lubricating oil is suitable for high-speed and high-temperature environments, while grease is more suitable for low-speed and normal temperature environments.

When disassembling bearings, appropriate pullers should be used to remove the bearings from the seat holes, and hard objects such as chisels or hammers should be avoided to prevent damage to the bearings. During the lubrication process, the condition of the lubricant should be checked regularly, and replaced or added in time to maintain a good lubrication effect.

The selection, use, disassembly and lubrication of bearings must be strictly in accordance with the specifications to ensure their stable operation and long-term durability in the equipment. Through these meticulous steps, not only can the occurrence of failures be effectively reduced, but the overall efficiency of mechanical equipment can also be significantly improved.

Welcome to contact us if you have any request about DSYC bearings!