News Center

How To Extend The Service Life Of Bearings?

2023-08-16

How To Extend The Service Life Of Bearings?

Extending the service life of bearings is crucial for improving equipment reliability, reducing maintenance costs, and avoiding downtime. Below are key strategies to ensure bearings operate efficiently for a longer period:

1. Proper Selection of Bearings

Application-Specific Bearings: Choose bearings designed for the specific load, speed, and environmental conditions of the application.

Material and Coatings: Opt for bearings made from high-quality materials or with specialized coatings to enhance wear resistance and corrosion protection.

2. Correct Installation

Avoid Misalignment: Ensure proper alignment during installation to prevent uneven loads on the bearing.

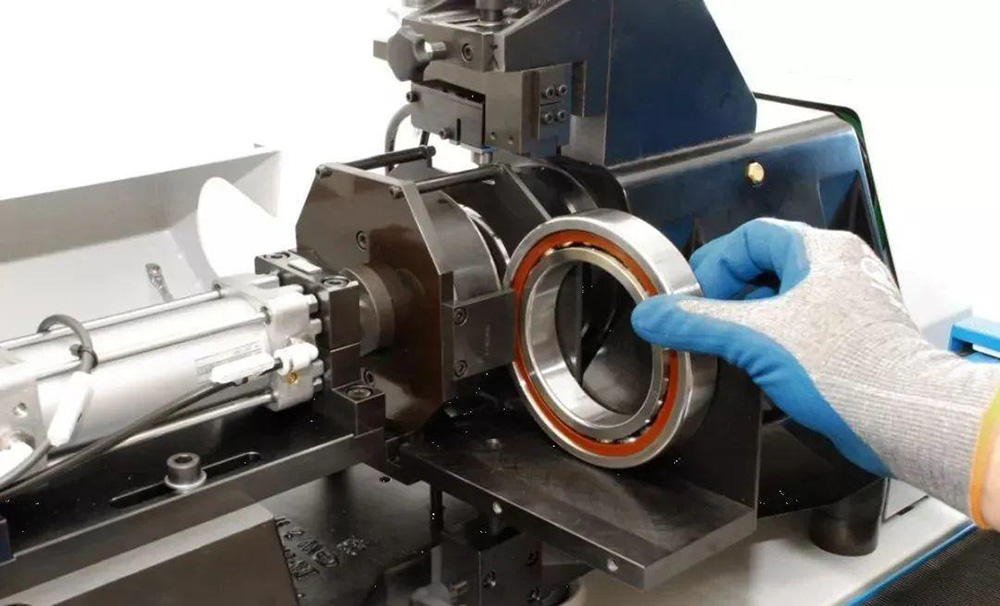

Use Proper Tools: Employ specialized tools such as bearing pullers and presses to prevent damage during installation or removal.

Follow Manufacturer Guidelines: Adhere to recommended installation procedures, including torque specifications and mounting techniques.

3. Lubrication Management

Use the Right Lubricant: Select the appropriate grease or oil based on the operating temperature, speed, and load conditions.

Maintain Proper Lubrication Levels: Over-lubrication or under-lubrication can cause premature failure.

Regularly Replace Lubricants: Monitor and refresh lubricants to avoid contamination and ensure optimal performance.

4. Regular Maintenance

Routine Inspections: Inspect bearings for signs of wear, noise, vibration, or overheating.

Clean Surrounding Areas: Keep the bearing and housing area clean to prevent contamination.

Check for Looseness: Ensure fasteners and bearing seats remain tight and secure.

5. Monitor Operating Conditions

Control Load and Speed: Avoid exceeding the bearing's design limits for load and rotational speed.

Temperature Management: Ensure adequate cooling to avoid overheating, which can degrade lubricants and materials.

Address Vibrations: Minimize vibrations and shocks that can lead to fatigue or surface damage.

6. Contamination Prevention

Use Seals and Shields: Employ appropriate seals or shields to protect bearings from dust, dirt, and moisture.

Proper Handling: Handle bearings with clean hands or gloves to avoid introducing contaminants.

Install Filtration Systems: Use filtration systems to prevent dirt and particles from entering the bearing environment.

7. Balancing and Alignment

Ensure Equipment Balance: Imbalanced equipment can cause uneven forces on bearings, leading to premature wear.

Proper Shaft Alignment: Misaligned shafts can result in axial or radial stresses on the bearing.

8. Periodic Condition Monitoring

Vibration Analysis: Monitor vibration levels to detect early signs of bearing issues.

Temperature Monitoring: Keep track of operating temperatures to identify overheating or lubrication problems.

Ultrasound Testing: Use ultrasonic devices to detect lubrication issues or early-stage bearing damage.

9. Stress Relief and Load Distribution

Preload Optimization: Set the correct preload for bearings to avoid excessive stress or looseness.

Load Distribution: Use multiple bearings or adjust designs to distribute loads evenly across bearings.

10. Upgrades and Modern Techniques

Ceramic Balls or Hybrid Bearings: In high-speed or extreme environments, consider hybrid bearings for greater durability.

Advanced Coatings: Apply wear-resistant or anti-corrosion coatings to enhance longevity.

11. Environmental Adjustments

Avoid Extreme Conditions: Protect bearings from extreme temperatures, high humidity, or corrosive environments.

Store Properly: Store bearings in clean, dry conditions to prevent rust and contamination before use.

12. Training and Expertise

Train Personnel: Ensure maintenance staff are trained in proper bearing handling, installation, and maintenance techniques.

Consult Experts: Seek advice from bearing manufacturers or specialists for critical applications.