News Center

How to maintain angular contact ball bearings?

2024-03-22

How to maintain angular contact ball bearings?

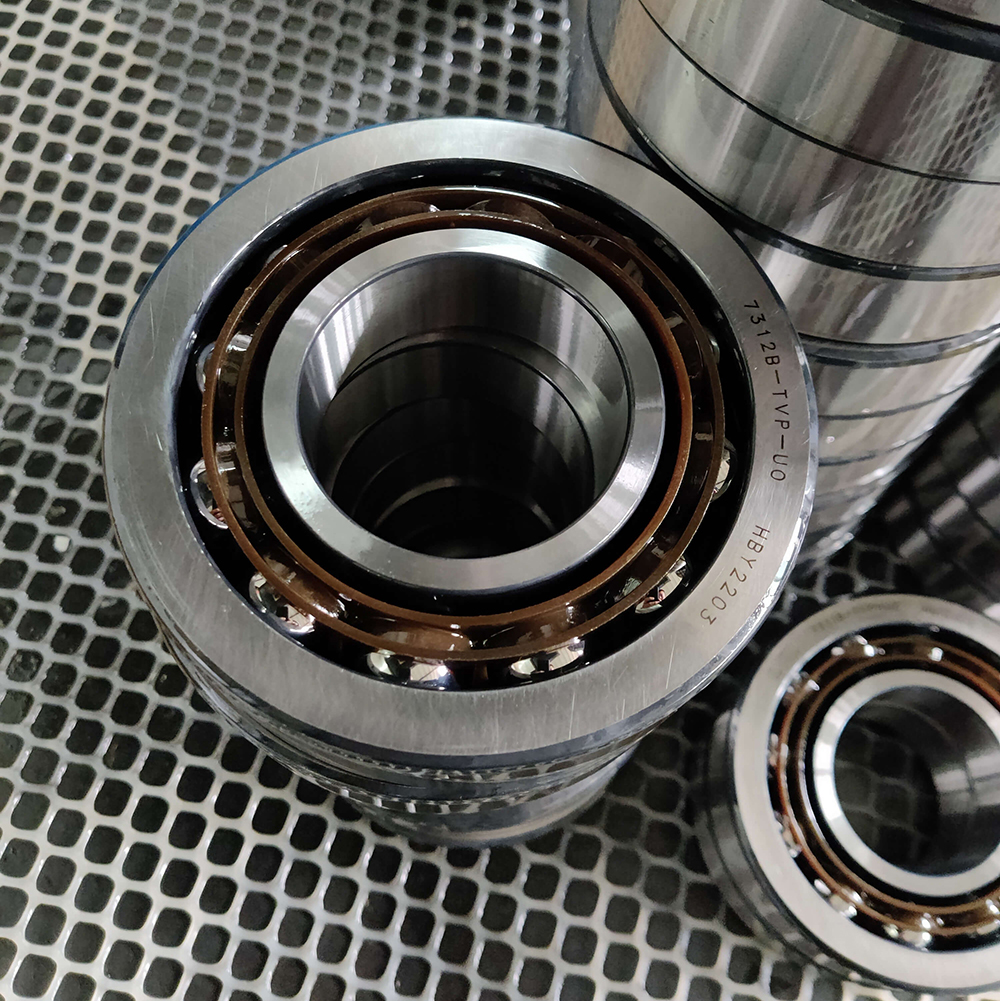

Angular contact bearings are divided into two categories: single-row angular contact bearings and double-row angular contact bearings, which are used in high-frequency motors and centrifugal separators. Angular contact bearings are a type of bearing with universal matching and basic design.

Angular contact ball bearings are mainly used for light-load high-speed rotation, requiring bearings to have high precision, high speed, low-temperature vibration and fixed service life. So how to maintain bearings?

1. After running for a fixed period of time (or maintenance period), completely disassemble the bearing;

2. Soak the bearing with diesel or kerosene, and open the sealing cover for cleaning if there are technical conditions;

3. After cleaning, the dry cleaning oil is inspected for damage;

4. Use a 150mm rod with the same diameter as the angular contact ball bearing (hollow tube is recommended) and fix each bearing;

5. When turning the bearing quickly by hand, push the rod (tube) to the ear or the microphone of the audio amplifier to hear the noise of the bearing turning;

6. After fixing the bearing, move the boom horizontally to check whether the bearing is worn or loose.

7. Bearings with serious looseness, excessive rotation noise, and serious defects should be eliminated and replaced with bearings of the same type;

8. Take a bucket of grease (high-quality yellow dry oil) and melt it with a low fire (not too hot), and soak the test bearing in the bucket until no bubbles overflow. The angular contact ball bearing is taken out before the grease cools down, and there is less grease residue. After the grease cools down, the bearing is removed, and the amount of remaining grease is very large, so the amount of remaining grease should be determined according to needs.

9. Clean the grease outside the bearing with a soft cloth or toilet paper, and assemble the bearing to the pulley as it is. The maintenance work will be completed.

Angular contact ball bearings are precision parts. Compared with ordinary mechanical parts, angular contact bearings have higher precision, so their use needs to be carried out with caution. No matter how high-performance bearings are used, such as precision bearings, aerospace bearings, magnetic suspension bearings, floating bearings, etc., if they are used improperly, they will not get the expected high performance, so bearing maintenance is very necessary.

If you have any questions about angular contact ball bearings, please free feel to contact us!