News Center

"Rotating Guardian" in the car: the technological power of deep groove ball bearings

2025-03-14

Behind every smooth driving, every precise turn, and even every brake of the car, there is a seemingly small but crucial mechanical component hidden - deep groove ball bearings. As the "joint" of modern industry, it silently undertakes key tasks such as support, noise reduction, and life extension in the car. Today, we will reveal how this "invisible hero" plays an irreplaceable role in the car.

1. What is a deep groove ball bearing?

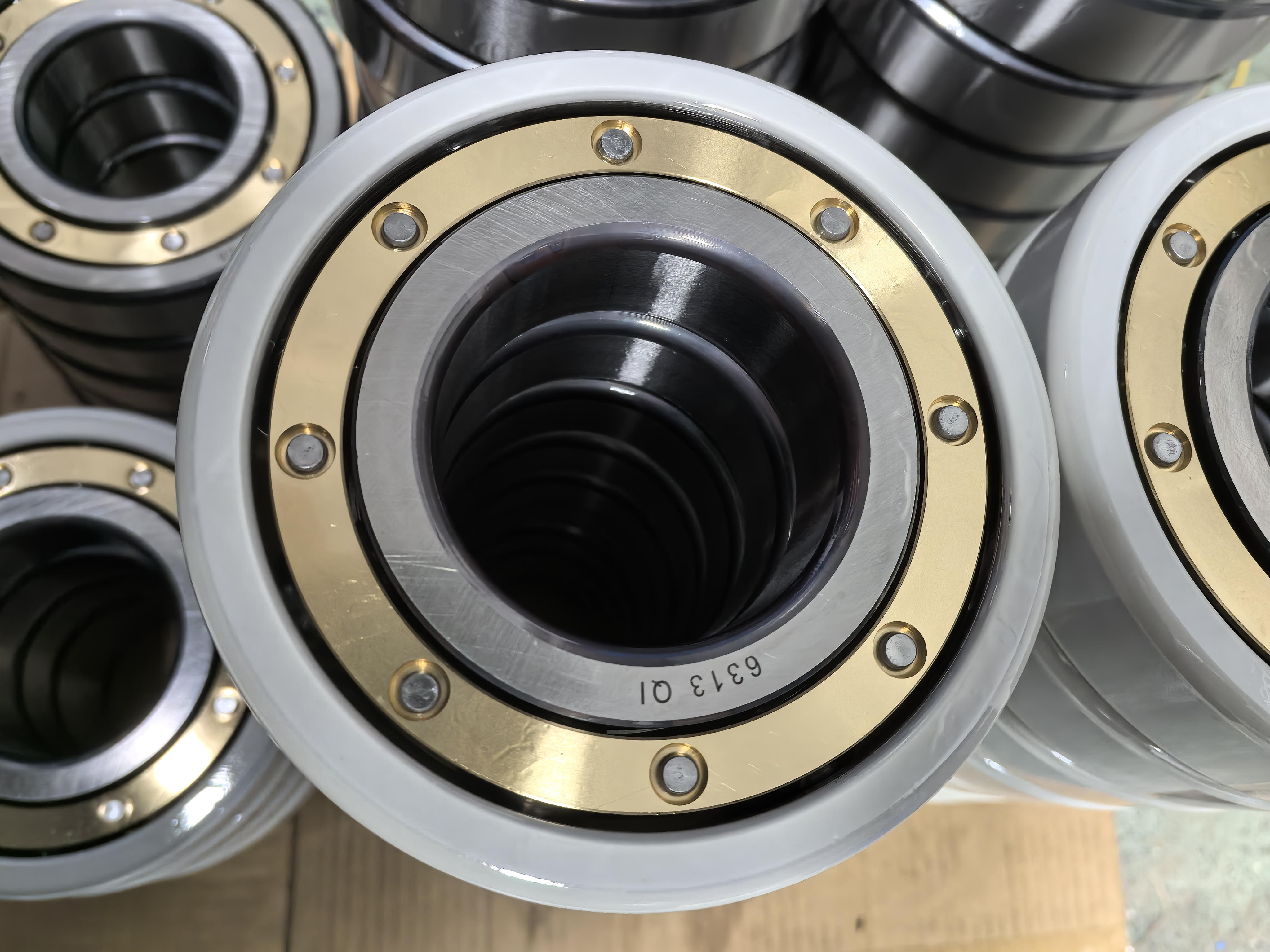

Deep groove ball bearings are the most common members of the bearing family. They are composed of four parts: inner ring, outer ring, steel ball and cage. The arc groove design of its inner and outer rings allows the steel ball to roll stably during high-speed rotation, and can withstand radial loads from the vertical direction, as well as a certain degree of axial load (such as impact force during rapid acceleration or braking). This "all-round" feature makes it one of the first choices for the automotive industry.

2. Four core applications of deep groove ball bearings in automobiles

Engine system: "lubricant" for power transmission

Inside the engine, deep groove ball bearings are used in accessory systems such as water pumps, generators, and air conditioning compressors. For example, water pump bearings need to work continuously at a speed of thousands of revolutions per minute in a high-temperature coolant and engine vibration environment to ensure stable operation of the cooling system. Without the lubrication and buffering of the bearings, the engine may "strike" due to overheating.

Wheels and drive shafts: make the car "run more steadily"

Deep groove ball bearings (or tapered roller bearing combinations) are installed inside the wheel hub of each car. They directly support the weight of the car body and withstand the impact of road bumps. The new generation of low-friction bearings can also reduce energy loss and increase the range of electric vehicles.

Gearbox: The "behind-the-scenes hero" of smooth gear shifting

The rapid switching of gearbox gears requires bearings to provide precise axial positioning. Deep groove ball bearings are responsible for the gear shaft support here. Their low vibration characteristics make the gear shifting process smoother and avoid frustration.

New energy vehicles: the "new stage" of the electric era

In electric vehicles, the application of deep groove ball bearings has been further expanded:

Drive motor: support the high-speed rotation of the motor rotor (some motors have a speed of more than 15,000 rpm), while withstanding electromagnetic interference and high temperature;

Charging system: the cable reel bearing of the charging pile needs to be frequently retracted and released, and the wear-resistant characteristics extend the life of the equipment;

Energy recovery system: helps to efficiently convert kinetic energy into electrical energy.

3. Why do cars "prefer" deep groove ball bearings?

Compact structure, space saving

The simple design of deep groove ball bearings makes it compact and suitable for the trend of lightweight automobiles. For example, the hub bearing unit (Hub Bearing Unit) integrates traditional multiple components into one through an integrated design, and the installation efficiency is increased by more than 50%.

Maintenance-free, cost-reducing

Modern automobile bearings generally use sealing technology and long-life grease to achieve "lifetime maintenance-free". Car owners do not need to refuel regularly, and car companies can also reduce after-sales costs.

Extreme environmental adaptability

Through special coatings (such as ceramic coatings), high-purity steel (such as vacuum degassed steel) and precision machining processes, bearings can work stably in -40℃ to 150℃, dusty or humid environments. For example, the bearings of desert off-road vehicles require additional dustproof design, while models in high-cold areas focus on low-temperature starting torque control.

4. Future trends: intelligence and material revolution

As cars move towards electrification and intelligence, deep groove ball bearings are also evolving:

Intelligent monitoring: bearings with built-in sensors can monitor temperature and vibration data in real time and warn of faults (such as self-sensing bearings in Tesla's patent);

New material breakthroughs: silicon nitride ceramic ball bearings are 60% lighter, and their insulation properties can prevent current corrosion of the motor shaft;

Ultra-high-speed challenges: For high-performance electric vehicles with speeds of more than 300 kilometers per hour, bearings need to break through traditional limits and adopt fluid dynamics optimization design.

Conclusion: Small bearings, big future

From fuel vehicles to new energy vehicles, from means of transportation to autonomous driving, deep groove ball bearings have always been an indispensable cornerstone of the automotive industry. Every rotation of the ball represents the perfect fusion of mechanical precision and human wisdom. In the future, with breakthroughs in materials science and Internet of Things technology, this "steel ball" may give cars more possibilities.

For more information, please contact us!