News Center

What are miniature bearings?

2018-08-28

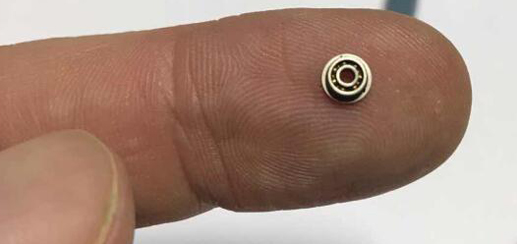

What are miniature bearings?

Miniature bearings are compact, high-precision components essential in various applications across multiple industries. Their small size allows them to operate effectively in confined spaces while providing low friction, high speed, and durability.

Miniature bearings typically have a diameter of less than 30mm and consist of an outer ring, inner ring, balls, and a cage. They are designed to reduce friction between moving parts, making them ideal for applications requiring smooth and reliable motion. Common materials used include chrome steel and stainless steel, with different types available such as deep groove ball bearings and angular contact ball bearings.

Applications of Miniature Bearings

- Medical Equipment:

Used in dental drills, surgical instruments, and laboratory devices, miniature bearings enhance precision and reliability.

- Robotics:

Essential for robotics applications due to their high precision and low torque characteristics, they help improve the accuracy of robotic joints and movements.

- Aerospace:

Critical in aerospace instruments and control systems where precision is paramount.

- Computers:

Found in hard disk drives, they facilitate smooth operation by reducing friction and vibration during high-speed spinning.

- Automotive:

Used in components like power windows and seat adjustments, miniature bearings contribute to the seamless operation of various automotive systems.

- Electronics:

Commonly applied in printers, scanners, and small appliances, they support efficient performance in compact designs.

- Industrial Applications:

Miniature bearings are utilized in motors and flow meters, enhancing efficiency and extending service life.

In summary, miniature bearings play a vital role in modern technology across diverse sectors by facilitating efficient motion in compact designs. Their continued demand reflects advancements in technology and the need for precision engineering solutions.

Welcome to contact us if you have any request about DSYC bearings!