News Center

What is your understanding of bearing pre-tensioning?

2022-01-25

What is your understanding of bearing pre-tensioning?

Bearing pre-tensioning is a critical process used in various applications to enhance the performance and longevity of bearings. Here’s an overview of its purpose, methods, and benefits:

Purpose of Bearing Pre-Tensioning

Elimination of Clearance: Pre-tensioning is applied to remove excess play or clearance in bearing systems. This is essential because standard bearings often have some designed-in clearance, which can lead to misalignment and sliding rather than rolling of the bearing elements if not properly preloaded.

Improved Rigidity: By applying a preload, the stiffness of the bearing system is increased. This rigidity helps maintain accurate positioning of the shaft and reduces runout, enhancing overall operational accuracy.

Reduction of Vibration: Pre-tensioning minimizes vibrations and noise during operation by ensuring that rolling elements are properly loaded, which can prevent issues like fretting and premature wear.

Compensation for Wear: Over time, wear and settling can create additional clearance in a bearing arrangement. Pre-tensioning compensates for this wear, helping to maintain optimal performance and extending service life.

Enhanced Load Distribution: Proper preloading helps distribute loads evenly across the bearing surfaces, reducing localized stress concentrations that could lead to failure.

Methods of Applying Pre-Tension

Solid Preload: This method involves holding the inner and outer rings of the bearing in place using spacers or locking mechanisms while applying an axial load. It provides high stiffness but may be sensitive to thermal expansion.

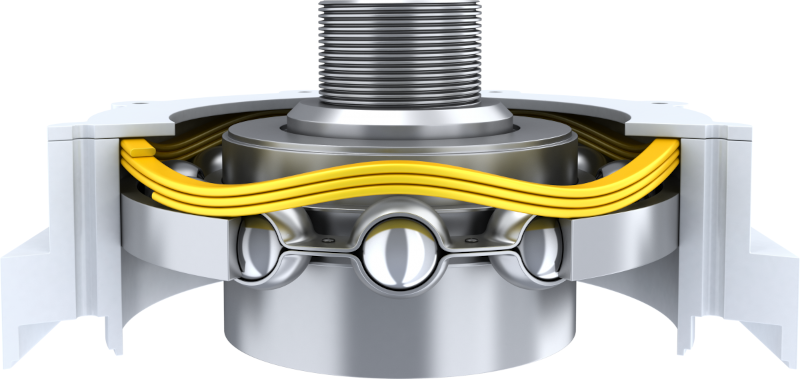

Spring Preload: A more common approach, spring preload uses coil springs or wave washers to apply a constant axial load to the inner or outer rings. This method is more forgiving of slight misalignments and temperature variations compared to solid preload.

Individual Adjustment: Each bearing in an assembly can be adjusted separately using nuts, shims, or other mechanisms to achieve the desired preload force.

Collective Adjustment: In this method, multiple bearings are adjusted together as a unit to achieve overall preload without individual adjustments.

Benefits of Bearing Pre-Tensioning

Extended Bearing Life: Properly preloaded bearings experience more favorable load distributions and reduced wear, leading to longer service life.

Improved Performance: Enhanced stiffness and reduced vibration contribute to better operational performance in applications requiring high precision.

Noise Reduction: By minimizing clearances and ensuring proper loading of rolling elements, pre-tensioned bearings operate more quietly than those without preload.

In summary, bearing pre-tensioning is an essential practice that enhances performance by eliminating clearance, improving rigidity, reducing vibration, compensating for wear, and ensuring even load distribution across bearing surfaces. The choice of preload method can significantly affect the operational characteristics and longevity of bearings in various applications.

Welcome to contact us if you have any request about DSYC bearings!