News Center

Wind Turbine Gearbox Bearings: Types Selection & Solutions for Global Buyers

2025-03-25

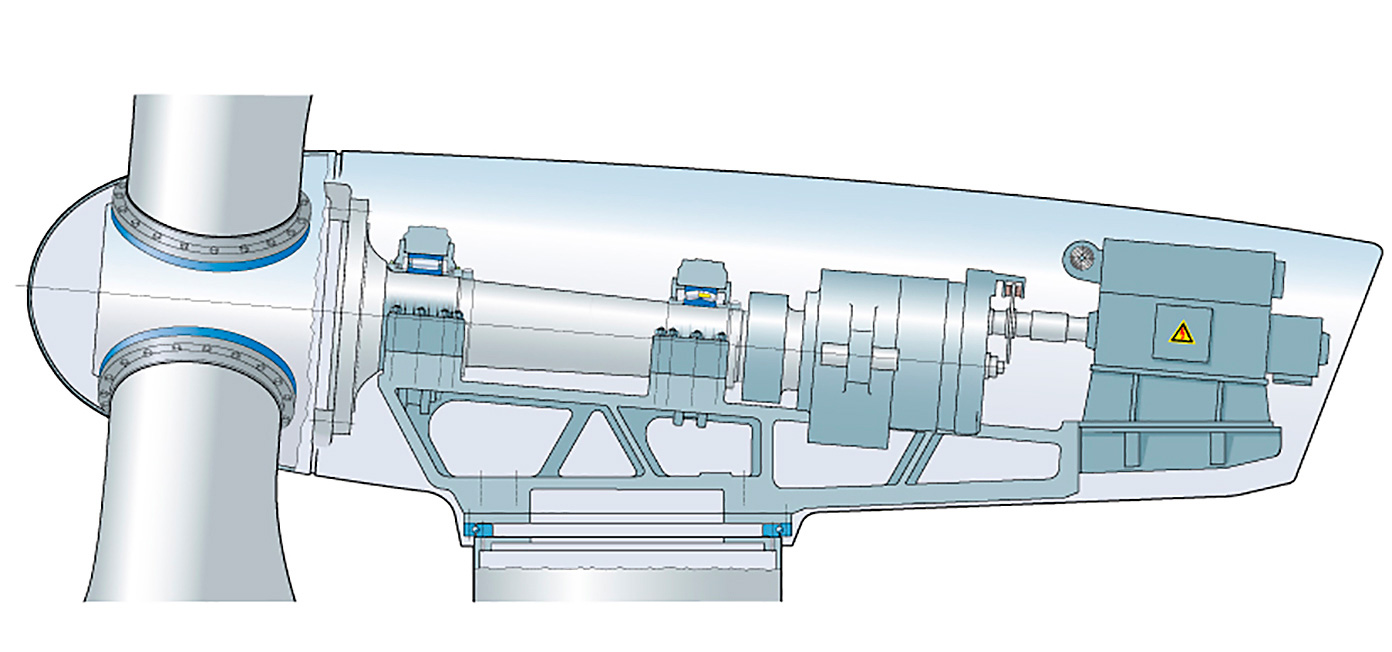

The Critical Role of Bearings in Wind Gearboxes

Wind turbine gearboxes are the "power converters" of renewable energy systems, transforming slow rotor speeds (10-30 RPM) into high-speed rotation (1,000-2,000 RPM) for electricity generation. At the heart of these gearboxes lie “high-performance bearings” that ensure smooth power transmission under extreme loads.

For global buyers sourcing wind gearbox bearings, understanding the right bearing types, technical specifications, and industry trends is essential for reliability and cost efficiency.

1. Key Bearing Types in Wind Turbine Gearboxes

(1) Low-Speed Shaft Bearings (Input Shaft)

Function: Connects to the rotor, withstands massive radial/axial loads from wind forces.

Recommended Bearings:

✔ Double-Row Tapered Roller Bearings (TDI Type)

- High radial + axial load capacity

- Self-aligning capability (±0.3°)

- Brands: SKF TDI, FAG 313, Timken 3800

✔ Spherical Roller Bearings

- Automatic misalignment compensation (±1°)

- Better for shock loads (e.g., gusty wind conditions)

(2) Intermediate Shaft Bearings

Function: Transmits torque between gear stages.

Recommended Bearings:

✔Cylindrical Roller Bearings (NU/NJ Series)

- Pure radial load handling

- Allows axial displacement (floating design)

✔ Tapered Roller Bearings (Single/Double Row)

- Combined radial + axial load support

(3) High-Speed Shaft Bearings (Output Shaft)

Function:Drives the generator at 1,500+ RPM.

Recommended Bearings:

✔ Angular Contact Ball Bearings (Paired 7200/7300 Series)

- Matched sets (DB/DF arrangement) for bidirectional thrust

✔ Deep Groove Ball Bearings (6200/6300 Series)

- Cost-effective for lower axial loads

(4) Planetary Stage Bearings

Function: Supports planetary gears in compact spaces.

Top Choices:

✔ Full-Complement Cylindrical Roller Bearings

- Maximum load capacity (no cage)

✔ Crossed Roller Bearings

- Handles radial + moment loads simultaneously

2.Cost vs. Reliability Trade-offs

European Brands:Top-tier reliability ,20-30% higher cost

Asian Suppliers :Competitive pricing ,Varying quality control

Remanufactured: 40% cost savings,Limited warranty

Selecting the right gearbox bearings directly impacts turbine uptime and ROI. With advancements in materials, sealing, and predictive maintenance, modern bearings now offer unprecedented longevity—even in the harshest environments.

Contact our sales team today for a free bearing selection consultation!