News Center

Can miniature angular contact ball bearings revolutionize the automotive industry?

2025-02-04

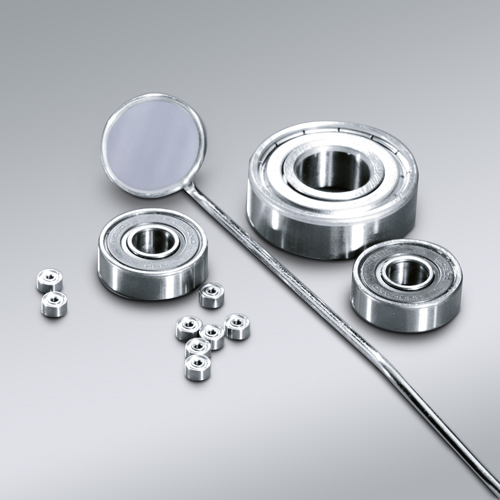

In recent years, the automotive industry has witnessed a surge in the adoption of advanced technologies to enhance vehicle performance, efficiency, and durability. Among these innovations, miniature angular contact ball bearings have emerged as a game-changer, offering a unique combination of precision, load-bearing capacity, and compact design. But can these tiny components truly revolutionize the automotive sector?

What Are Miniature Angular Contact Ball Bearings?

Miniature angular contact bearings are specialized bearings designed to handle both radial and axial loads simultaneously. Unlike traditional bearings, which are primarily designed to handle either radial or axial loads, angular contact bearings can manage combined loads, making them ideal for applications where space is limited, and precision is paramount. These bearings are characterized by their small size, high-speed capabilities, and ability to operate under demanding conditions.

Applications in the Automotive Industry

The automotive industry is increasingly turning to miniature angular contact ball bearings for a variety of applications, including:

- Electric Vehicles (EVs): As the world shifts towards electric mobility, the demand for compact, high-performance components has never been greater. Miniature angular contact bearings are being used in electric motors, where they help reduce friction, improve efficiency, and extend the lifespan of the motor. Their ability to handle high speeds and loads makes them particularly well-suited for the demanding environment of an EV powertrain.

- Advanced Driver-Assistance Systems (ADAS): Modern vehicles are equipped with a range of sensors and cameras that enable features like lane-keeping assistance, adaptive cruise control, and automatic emergency braking. Miniature angular contact bearings are used in the actuators and motors that control these systems, ensuring smooth and precise operation.

- Transmission Systems: In both manual and automatic transmissions, miniature angular contact bearings play a crucial role in reducing friction and wear, leading to smoother gear shifts and improved fuel efficiency. Their compact size allows for more efficient packaging within the transmission, freeing up space for other components.

- Steering Systems: Precision is key in steering systems, where even the slightest deviation can affect vehicle handling. Miniature angular contact bearings are used in electric power steering (EPS) systems to ensure accurate and responsive steering, enhancing both safety and driver comfort.

Challenges and Future Prospects

While the benefits of miniature angular contact ball bearings are clear, their adoption in the automotive industry is not without challenges. The production of these bearings requires extremely high precision, which can drive up costs. Additionally, the materials used must be able to withstand harsh operating conditions, including high temperatures, vibrations, and exposure to contaminants.

However, as manufacturing techniques continue to advance, the cost of producing these bearings is expected to decrease, making them more accessible to a wider range of automotive applications. Furthermore, ongoing research into new materials and coatings could further enhance their performance and durability.

Conclusion

The integration of miniature angular contact ball bearings into the automotive industry represents a significant step forward in the quest for more efficient, reliable, and high-performing vehicles. While challenges remain, the potential benefits are too great to ignore. As the industry continues to evolve, these tiny yet powerful components may well play a pivotal role in shaping the future of automotive technology. So, can miniature angular contact ball bearings revolutionize the automotive industry? The answer seems to be a resounding yes.

If you have any questions about miniature angular contact ball bearings, please don't hesitate to contact us!